Container welding machine

This welding machine has been operating in two shifts since 2010 without stopping for 12 years.

Welding machine not only make the production automated but also intelligent.

These containers are ordered by different customers, with different specifications and process requirements. The flexible SKV instrument automatic welding solution has many preset functionalities that have been installed on the robot, enabling the system to make rapid changeovers, seamlessly.

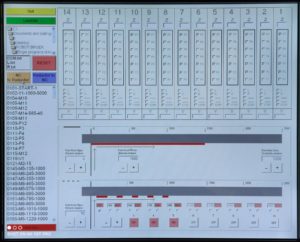

Intuitive control of the welding machine

Traditional manual welding comes with many problems including shape deficiency and width change by the welding wire and welding flow. However, in automatic welding the welded parts have consistent shapes and the seam width is stable, thanks to the excellent repeatability and motion control of SKV welding machine. Moreover, automatic welding reduces the occurrence of pores, making the welding seam of the container more aesthetic.

Built-in NC program editor – 2 minutes and a new program is ready.

Nowadays, the workers just need to monitor the panel production and know only how to operate the welding machine.The CNC can be connected to the Internet for remote diagnostics.The CNC supports various languages English, Italian, Polish, Estonian, Indian.

We also offer a complete solution.

1) Welding robot machine with two welding CEA Robocase 5000 400V and two welding tables

2) in the corner of each welding table there is a mast with a suspended welding CEA MAXI 315, a radius of 5 meters for preliminary welding of sheets to each other to prevent their displacement.

3) Vertical narrow welding table with hydraulic clamp. For manual welding of container top tube (round and square) and boxes with hook holes. The table is equipped with a mast for an overhead welding CEA DIGITECH VP 2 . On this table the outer seam of the container is welded.

4) Banana welding table for welding the top pipe of the container. For welding the inside seam of a container. On the table it is possible to move the hands of the hydraulic clamps for different container lengths.

5) Frame stand transformer (fixed to the floor) for storing finished items vertically. This saves space and speeds up the process.

If you are ready to speed up the production of containers, then this solution is for you!